About SUNTEAM custom bag factory

Who We Are

Sunteam started as a small workshop focused on high-quality leather bags and other leather accessories. The founder, Delia, began her journey in foreign custom bag trade sales. With a strong passion for bag craftsmanship and a sharp understanding of customer needs, the company grew into an international bag manufacturer offering design, production, and export services.

Over the years, Sunteam has expanded its factory capacity and exported to many countries, helping customers reduce costs and enjoy reliable custom bag solutions worldwide. Do you have questions about craftsmanship or need a bunch of custom bags? No worries — we’re here to make it happen!

Partner of Sunteam for 10 years, I have always ordered custom bags from them. Because they have a Complete supply chain system. No natter which kind of bags I inquired, They can give me a quick feedback. At the same time,they have a good after sales service. What impressed me most is that when I recieved the 1000pcs of bags in last Oct. We found there are 3pcs bags defect. The feets of bag fall out. After discuss with Sunteam. They immediate send me 15 sets of feets and the tools to re-pair. And arranged local works come to re-pair.What’s more, they make 8 more pcs for next order to compensate me.

30+

Years

Our Mission

Working to improve the custom wholesale bags manufacturing industry through better craftsmanship, innovative design, and sustainable practices.

Our goal is to provide our customers with a diverse range of high-value products and the highest level of service that not only meets their specific needs but also helps them to be successful.

Our Vision

To become a globally recognized top custom wholesale bags manufacturer, setting industry standards in product quality, design innovation, and sustainable bag manufacturing practices.

At the same time, we strive to be a responsible company that:

- Creates a positive and fulfilling work environment for employees.

- Builds trust and reliability with customers.

- Earns respect from society through ethical and sustainable practices.

Our Values

- Craftsmanship and Quality – Guided by Italian expertise, we persue the highest standards in every detail.

- Innovation – We embrace new technologies and trends to offer unique, functional, and stylish products.

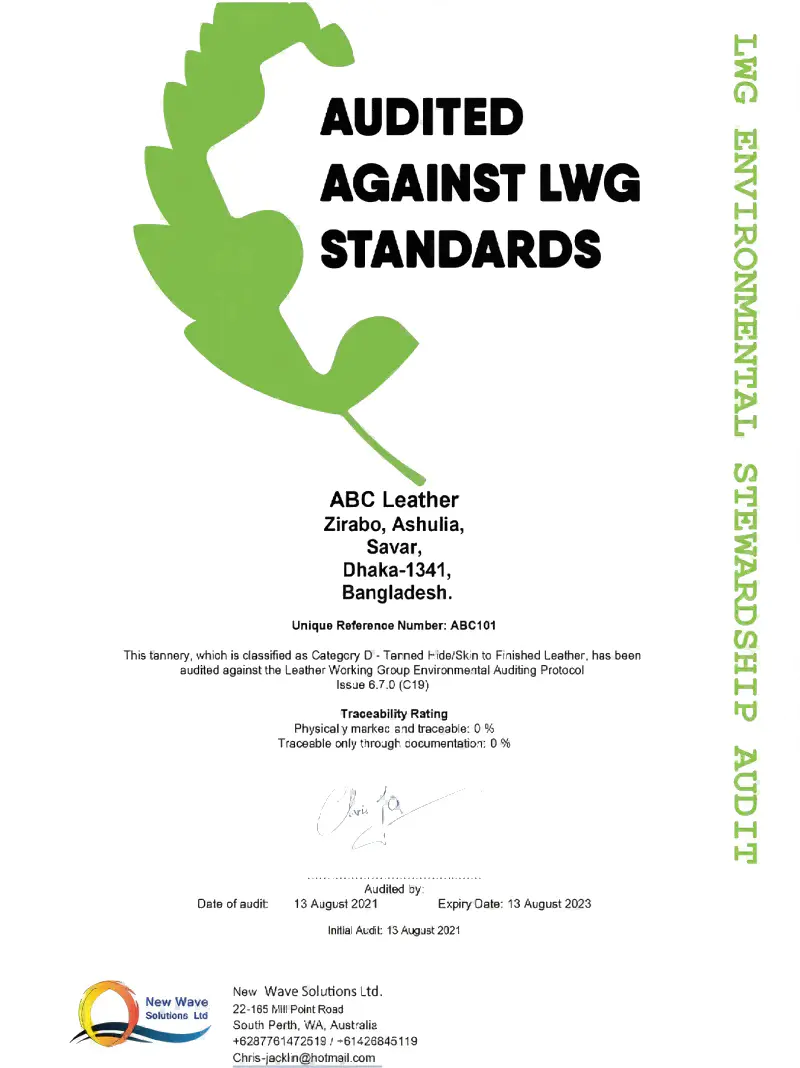

- Sustainability – We prioritize eco-friendly materials and responsible production to reduce environmental impact.

- Customer Focus – We tailor solutions to meet diverse client needs, fostering long-term partnerships.

- Integrity and Responsibility – We source materials ethically, treat workers fairly, and run our business with honesty and transparency.

How We Work

Sunteam is good at custom bag manufacturing and has a wide range of bags for global market and professional bag factory. Our product includes premium leather handbags,totebags,crossbody bags, backpacks, sports bags, laptops, bike bags, and other leather accessories. In addition to bag production, we also provide bag design consultation, material selection teaching, make bag prototypes, and we have a comprehensive QC system to ensure that each product perfectly reflects our customers’ needs.

As a professional wholesale bags manufacturer support many kinds of materials and technologies to produce mass orders and Low MOQ. We pride ourselves on providing flexible production options while promising consistent quality across all products. Every Sunteam custom product represents our confidence in functional design, durability, and aesthetic appeal.

01

Quick Response

02

Requirement Confirmation

03

Proposal & Quotation

All Kinds of customers

04

Sample Confirmation

05

Order Confirmation & Production

06

Quality Control & Delivery

No Matter Who You Are

01

Fashion and Retail

Creating premium branded handbags and leather accessories for boutiques and major retailers

Corporate and Promotional

Developing customized bags with company logos for events, employee gifts, and marketing campaigns.

Sports and Fitness

Designing performance-oriented bags for athletes and fitness enthusiasts

sunteam bags solutions

Sunteam provides comprehensive solutions to help solve the challenges of custom bags

Design Innovation

Professional design team works with clients to transform concepts into functional and beautiful products that stand out in the market.

Material Selection

Provide guidance on selecting the best materials based on performance requirements, beauty, cost, and sustainability goals.

Production Efficiency

Improve bag manufacturing processes to ensure consistent quality while meeting our customers’ timelines and budgets.

Inventory Management

We have the storage capacity to keep customers’ goods. Any time they need, we will ship to them accordingly.

Quality Assurance

Strict testing and inspection to ensure that each leather bag meets international standards.

Sustainability Solutions

Help customers reduce their environmental impact by providing eco-friendly materials and low-carbon bag production processes.

Our History

2013

Sunteam founded a custom bag factory in Bangladesh, focusing on producing high-quality leather products. In the middle of the same year, Italian office established.

- Providing professional material consulting.

- Assisting customers to find popular leather.

- Providing technical guidance to factory workers in Bangladesh.

2015

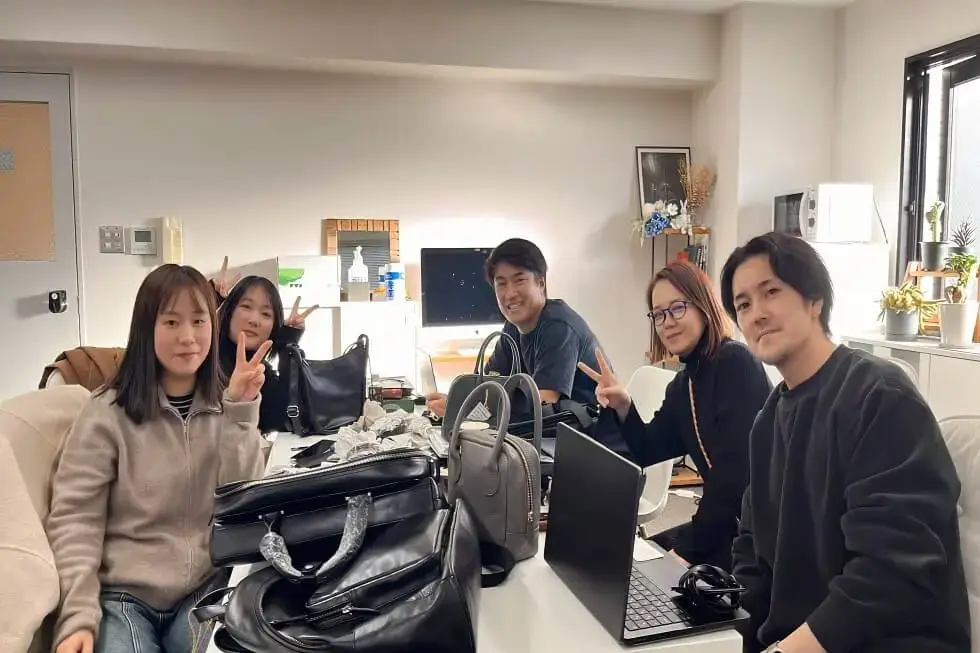

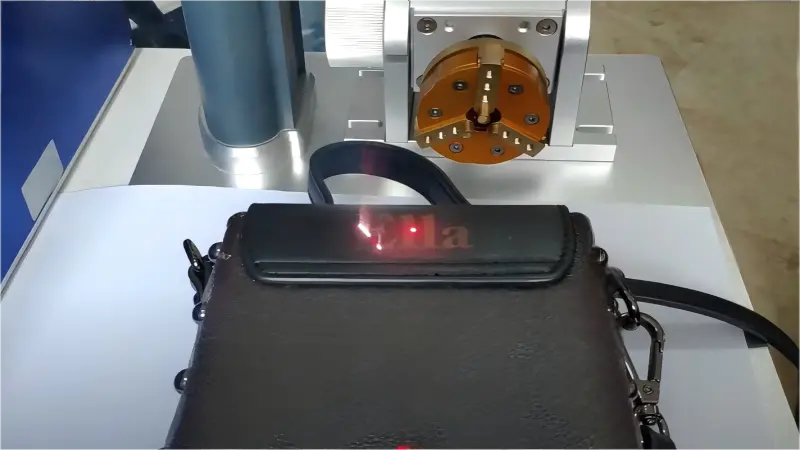

In 2015, officially entered the Japanese market and visited Japanese customers. In response to their high standards for leather products, we provide different leather articals to meet their budgets and optimize the hot stamping process, and successfully obtained a testing order. The customer is satisfied with our quality. The re-peat order and new development are continuing.

2016

Invited Japanese customers to visit the bag factory in Bangladesh and established a long-term cooperative relationship.And continue to work hard to become a more professional bags manufacturer.

2017

Sunteam further expanded in the European market and established stable partnerships in Italy, Germany, the United Kingdom, France, Spain, and other countries and cooperated with LIU-JO and PIQUADRO for Collistar to expand international business. The company actively participated in exhibitions in the European market, connected deeply with local brands, and provided customers with customized bag solutions that better met the needs of the European market.

2019

In 2019,cooperated with Russian customers to launch a specially customized sports series of bag products, including sports backpacks, fitness bags, travel sports bags, etc., which won the recognition of the Russian market for the excellent craftsmanship and innovative design.

In 2024, the company was invited to participate in the Russian International Exhibition to further consolidate its brand influence in the local market and continue to expand its business in Russia and surrounding markets.

2023

In 2023, with the rapid growth of business in the Japanese market, the company established an Osaka office and hired professional Japanese specialists to focus on serving Japanese customers and expand the local market.

In order to respond to market demand more accurately, provide more efficient customized services, and ensure that every customer can obtain high-quality bags that meet the brand’s tone, Japanese team localized the luggage industry. From design to imported high-end leather, we are committed to every link to ensure the satisfaction of every customer.

Best Bag Wholesalers: How do we produce outstanding leather bags?

Superior technology is one of the reasons why our bags surpass our peers. We also focus on continually optimizing our production processes to keep them error-free and produce better leather bags.

Our design department uses CAD software and 3D modeling technology to draw detailed bag prototypes on computers, helping to shorten development time while improving accuracy. These digital tools allow customers to see the details of custom bags before production, promoting collaboration.

In the material processing stage, we use the intelligent cutting bed to accurately cut multiple layers of materials, just like drawing with an electronic ruler, and the error of each piece of leather or cloth does not exceed 1 mm. This system can automatically calculate the most material-saving arrangement, saving 15% of materials compared to traditional manual cutting. Whether it is an order of 5,000 or 100, every inch of raw materials can be used efficiently like a puzzle.

In the sewing workshop, the intelligent sewing machine moves along the route set by the computer, and the key parts are manually reinforced by a master with 20 years of experience.

Especially in the corners and zippers that are prone to wear, we use a double sewing process – first the machine sews a straight basic stitch, and then the craftsman manually reinforces it with wax thread, which not only maintains efficiency but also makes the bag more durable.

Each workshop is equipped with an “electronic eye” system composed of high-definition cameras and sensors, which can track production progress in real time. In the 12 processes from cutting pieces to finished bags, key links must be photographed and archived. For example, when installing hardware fasteners, the system will automatically detect the installation angle of the metal parts. If the deviation exceeds 3 degrees, a red light will be turned on to remind rework.

All finished bags must pass the “three-level checkpoint” inspection: first check the weight with an electronic scale (to prevent missing accessories), then check the size accuracy with a laser scanner, and finally have a quality inspector simulate daily use scenarios for testing – such as repeatedly opening and closing the zipper 200 times, and load-bearing tests with 10 kg of items. Only bags that pass all tests will be tied with our exclusive quality card.

Cutting Equipment

Multiple CNC precision cutting machines capable of handling various materials with accuracy to 0.1mm, ensuring perfect pattern replication across production runs

Embossing and Debossing Systems

Hydraulic high-pressure embossing machines (up to 150 tons of pressure) create precise brand impressions and decorative elements

Heat Sealing Equipment

FIndustrial-grade heat sealing machines operating at controlled temperatures (120-180°C) provide waterproof seaming for specialty products

Stitching Technology

Advanced programmable stitching stations with multi-needle capabilities deliver consistent stitch quality at speeds up to 3,000 stitches per minute while maintaining precision

Printing Technology

Digital direct-to-material printers with 1200 DPI resolution allow for vibrant, durable graphics that withstand regular use and are ideal for custom needs requiring intricate patterns.

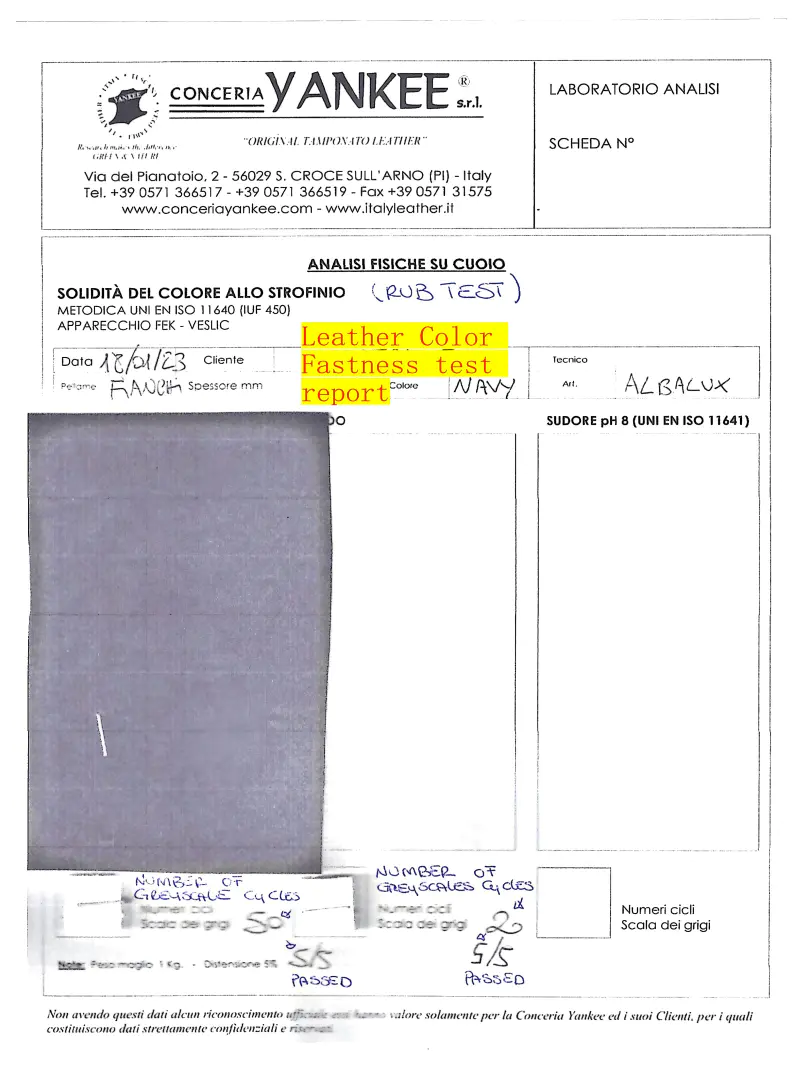

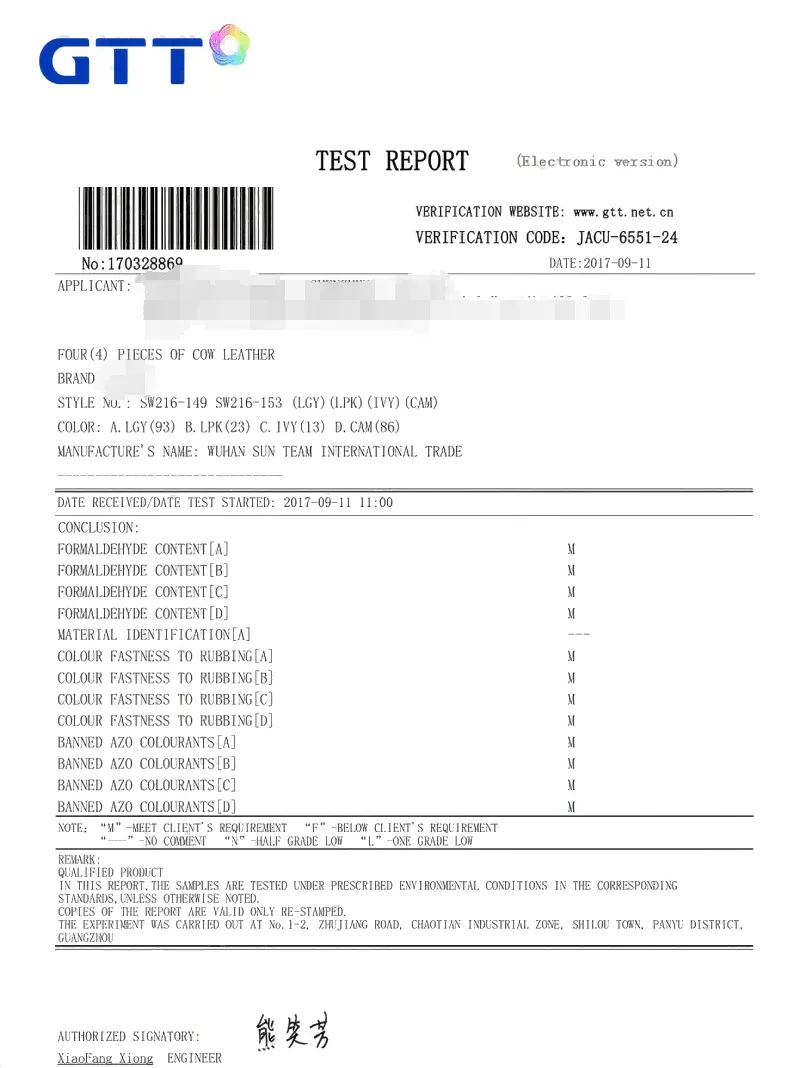

Testing Equipment

Laboratory-grade testing apparatus for material strength, color fastness, and Salt spray test ensures product durability meets specifications to achieve the effects of no fading.

Professional Bag Factory

Custom bag manufacturing capabilities aim to deal with diverse production requirements by efficiency and flexibility.

- Product Diversity: Simultaneous production lines can make up to 20 different kinds of bags without influencing quality or efficiency

- Material Processing: Our equipment accommodates diverse materials, including full-grain leather (processing 5,000 square feet daily),vegetable leather,wax leather, synthetic fabrics (12,000 yards weekly), and specialty materials like waterproof textiles

- Customization Scale: The Production Department custom orders from 100 units to full-scale production runs of 100,000+ units with consistent quality

- Production Speed: Standard lead times range from 30-60 days based on different materials of bag approval to shipping, with expedited options available for urgent requirements

- Seasonal Flexibility: Adjust bag manufacturing to accommodate seasonal demand fluctuations, maintaining consistent delivery timelines throughout the year

This balanced bag production infrastructure supports to serve diverse client needs, from emerging brands requiring smaller production runs to established companies with high-volume requirements.

Quality Control Systems

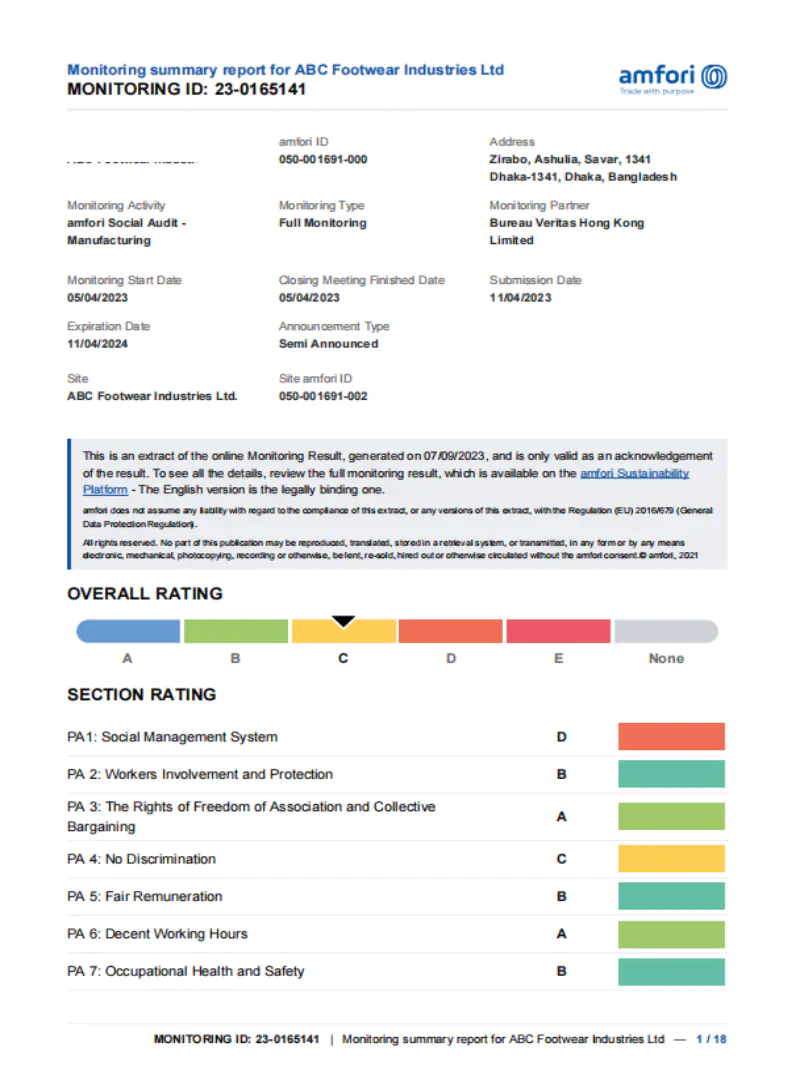

Quality assurance is integrated throughout the manufacturing process through our comprehensive Six-Point Quality Control System:

- Material Inspection: Every incoming material batch undergoes laboratory testing for consistency, durability, and conformance to specifications before entering production,such as color fastness, tensile strength, thickness uniformity, etc. to ensure consistency, durability and compliance with specifications.

- Pre-Production Verification: Master samples are created and approved for each production run, establishing clear quality benchmarks for the manufacturing team,and multiple standard sample bags are made before each batch of production to accurately control dimensional tolerances.

- In-Process Monitoring: Dedicated quality inspectors conduct systematic checks at critical production stages, with statistical sampling methods ensuring comprehensive oversight.The cutting stage, sewing stage, and assembly stage are recorded at fixed intervals.

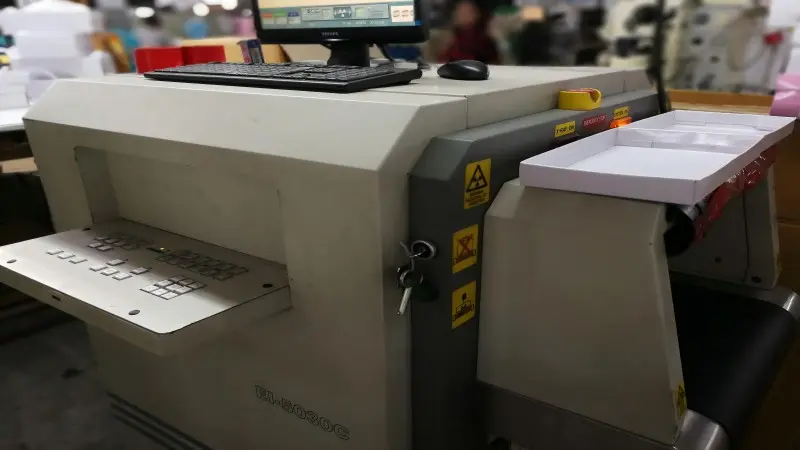

- Automated Detection: Computerized X-ray systems can reveal defects that are difficult to detect with the naked eye, especially in bag stitching and structural components

- Comprehensive Final Inspection: Each finished bag is thoroughly inspected according to 34 standards (with great value placed on the use of needle detectors to enhance product safety and reliability through fine inspection and to achieve zero needle residue).

- Batch Testing: Random custom bag samples from completed batches undergo stress testing simulating real-world usage conditions to verify durability and performance.

- 3rd party inspection: Arrang the 3rd inspection company company to our factory to 100% inspect.

We have a detailed record and traceability system that can clearly track the material source and production team of each bag. Our quality management system complies with ISO 9001 standards, and we conduct regular internal audits and continuously optimize the wholesale bags production process to ensure that only high-quality products are produced.

Why We’re Different

What truly distinguishes Sunteam in the custom bag manufacturing industry is our comprehensive integration of artisan craftsmanship with advanced manufacturing technology, creating a unique production approach we call “Precision Craftsmanship.” This methodology combines the attention to detail and quality of traditional handcrafted production with the consistency and efficiency of modern manufacturing systems.

Material Expertise

Our expertise in sourcing and using premium materials, especially Genuine Leather and technical fabrics, enables us to produce bags that are both stylish and versatile. We have builded strong relationships with over 20 exclusive material suppliers, providing many customers with unique options not available to other companies.

Customization Depth

While many bags manufacturers offer limited customization, offers true design flexibility with over 100 material and Pantone color options. Our design team can provide a higher level of customization than the industry standard based on customer needs.

We also accept localized customization. In addition to meeting your needs, we can further improve the quality of bags and help you order a satisfactory bag.

Production Flexibility

Our factory supports high-volume production and flexible small orders without compromising quality or efficiency. This flexibility method allows us to provide bag manufacturing services for established brands with stable demand, as well as meet the growing bag production needs of emerging brands.

ODM/OEM Sevice

Additionally, we offer personalized service, ensuring that each client’s specific needs and preferences are seamlessly integrated into our production process, resulting in bags that not only meet but exceed expectations.

Certifications for Your Perfect Custom Bag Project

Creative Custom Bag Team& Bag Manufacturer

Cara Wang

Prototype Developer

Both an optimistic mindset and hard work are important. As long as we maintain a positive attitude, we can surely overcome numerous challenges. Only by taking action will we know the outcome.

Delia Wang

Chief Executive Officer

While pursuing the material and spiritual happiness of all employees, we provide customers with a diverse range of high-value products and exceptional services, becoming a global disseminator of love.

Qian Tang

Textile Designer

Life is about constantly challenging the impossible. By thinking of different solutions, the impossible can definitely be turned into possible.

Get Free Sample

+86-27-85570058

+86-27-85570058

Location

Room# 101, Building#3, LanHai Garden, Huai Hai Road, Jiang Han District, Wuhan City, Hubei, China, 430015

Get In Touch